Our concept

The Isobox Concept: Four Core Principles

Innovative Wet-in-Wet Manufacturing Process

Our cutting-edge Wet-in-Wet production technique ensures superior strength and durability across all Isobox polyester boxes.

This method allows the panels to bond and settle before the drying phase, creating a seamless, ridge-free design, particularly in the sidewalls. The result is a reinforced floor, capable of withstanding heavy and frequent loads, ensuring long-lasting performance.

Italian Craftsmanship and Design

Isobox prides itself on combining advanced manufacturing with Italian design excellence. Our process delivers products with robust floors, smooth sidewalls, and an extended lifespan.

By adhering to our Wet-in-Wet process, we enhance structural integrity, offering resistance to heavy usage. This attention to detail embodies the elegance and durability synonymous with Italian craftsmanship.

Isobox: A Legacy of Durability, Customization, and Security

By choosing Isobox, you invest in more than just a box—you gain a trusted partner committed to quality and excellence.

Our attention to detail, durable construction, and customization options ensure that Isobox isothermic solutions meet the highest industry standards, providing secure and reliable transport for years to come.

Leaders in ATP-Certified Isothermic Boxes

With over 45 years of specialized expertise, Isobox Srl, based in Cesena—a hub for isothermic boxes production—leads the market in Europe. From large semi-trailers to compact small boxes, our durable and customizable solutions meet the diverse needs of clients in local and international distribution.

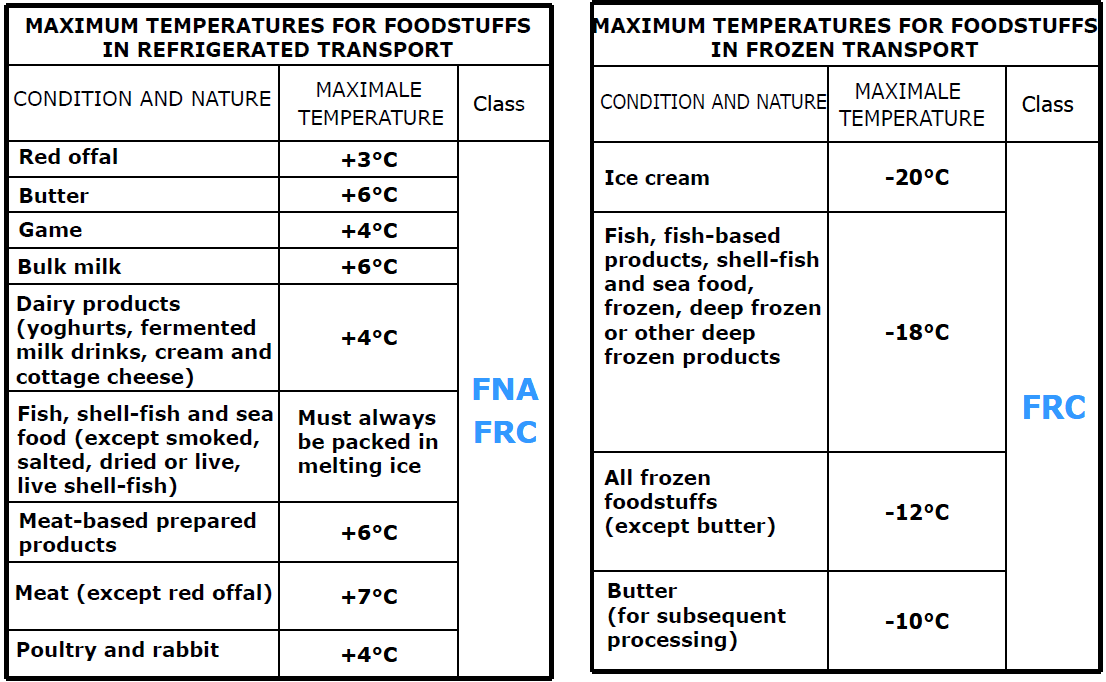

All bodies built by Isobox are ATP certified. This is a European standard for insulation values and cooling performance. This means that a body has the ability to handle a temperature between +12°C and -20°C, during an outside temperature of +30°C.

With ATP/FRC approval, Isobox boxes are suitable for transport throughout Europe.